Small satellites: Accion’s module definitely democratizes the space.

|

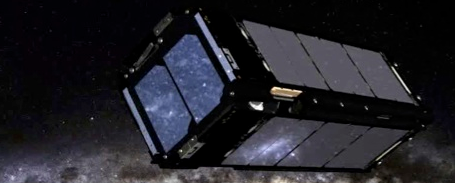

| SmallSat. |

So far,

we know CubeSat with its powerful abilities to provide low-cost

satellites, which are becoming increasingly popular tools for Earth-imaging,

communications, and other helpful applications.

But a set of major control

issues hamper this momentum including: lack

of accuracy to point cameras or change orbit; regular crash and burn within a

few months, and more.

These satellites lack a viable propulsion system, recalls MIT aeronautics

and astronautics alumna Natalya Brikner PhD ’15, co-founder and CEO of

Accion Systems. “You can make a satellite the size of a softball with a

surprising amount of

capabilities, but it can’t maneuver properly and falls from

orbit quickly,” she says.

Henceforth we can rely on Accion’s module, a new commercial electrospray

propulsion system, to deeply democratize the space.

Connectikpeople.co recalls that, Accion’s first commercial system is MAX-1,

a module that can push around a CubeSat, or a slightly larger satellite. MAX-1

can provide about 100 micronewtons of force per square meter.

Accion is on target to launch MAX-1 in July, and plans to start shipping

the system to customers by the end of the year.

In the milieu where, dozens of small satellites are launched annually, the

system could also help control how long they stay in space; (don’t become

floating space junk).

Accion’s propellant is a liquid salt material, similar in structure to

common table salt.

With that novel propellant, and a simple design, Accion can

batch-manufacture modules — much like computer chips — in quantities of around

200 at once.

According to Brikner, this costs about one-tenth as much as other

electric-propulsion systems.

Accion is now headquartered at Greentown Labs in Somerville, Massachusetts.

In the future, Lozano says Accion’s system could enable small satellites to

perform tasks now possible only for much larger satellites — such as exploring

the moon.